Water slide decals (or slip

decals) are water-mounted decals generally

printed face up and rely on the dextrose corn

sugar residue from the decal paper to bond the decal transfer to a surface. A

water-based adhesive layer can be added to the decal to create a stronger bond

or may be placed between layers of lacquer to

create a durable decal transfer. The paper also has a layer of glucose film

added prior to the dextrose layer which give it the adhesion properties, the

Dextrose layer give the decal (lubricity) the ability to slide off the paper

and onto the substrate.

Water slide decals are thinner

than many other decorative techniques (such as vinyl stickers)

and as they are printed, they can be produced to a very high level of detail. As such,

they are popular in craft areas such as scale modeling, as well

as for labeling DIY electronics

devices, such as guitar pedals.

Until recently, water slide

decals were professionally printed and only available in supplied designs, but

with the advent of printable decal paper for colour inkjet and laser printers, custom

decals can now be produced by the hobbyist or small business. Even without

this, decals have been made at home by modellers. Gummed paper tape was used as

a base and adhesive, with layers of hair spray (a shellac varnish)

built-up to form the transparent layer. The difficulty with this in the 1970s

was in printing the coloured image neatly by hand, as this pre-dated accessible

computer printing.

How to Apply UV decals /

Waterslide Decals with Alps Printer

Introduction

This article gives

general information about waterslide decals and a step-by-step guide showing

how decal printer,

waterslide decal printer, decal printing(with Alps printers) should be applied.

Background

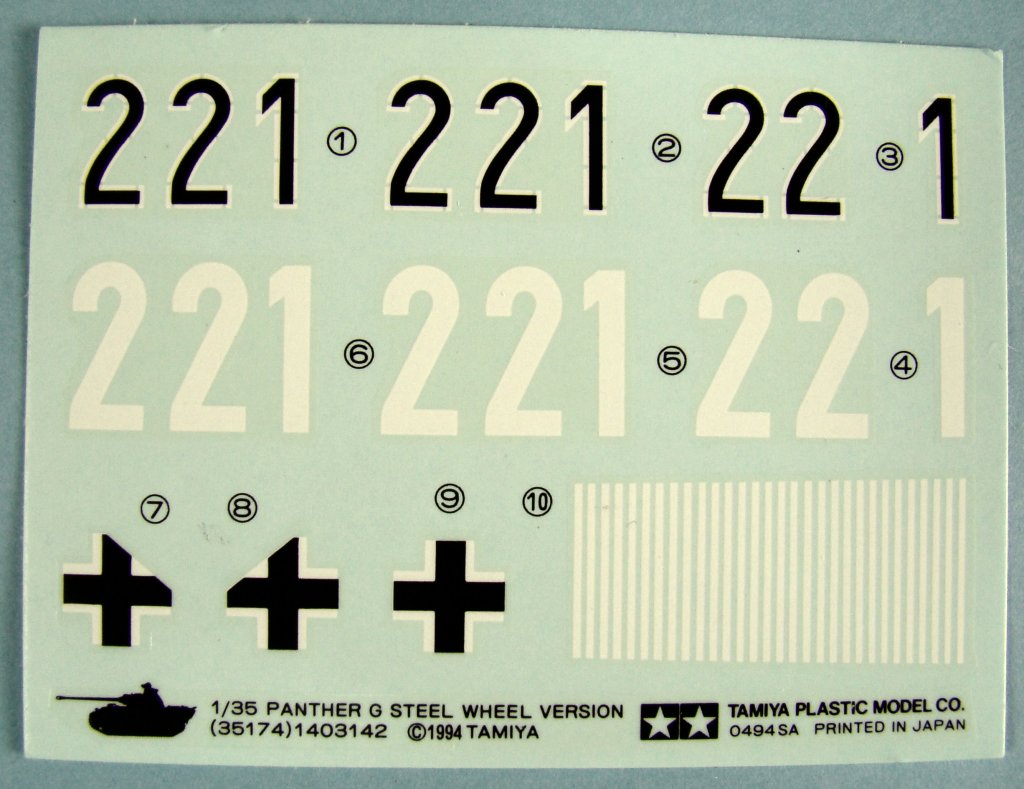

Waterslide

decals are by far the most popular way of applying unit markings and other

graphics to scale models. This is partly because most model kits are

supplied with appropriate waterslide decals, but also because they generally

work very well in most situations and it is relatively easy to get a good

result.

Waterslide

decals can vary considerably in quality. Sometimes they are too thick and

will stick out on the surface of the model and will not lie flat over surface

details. At other times, they may be too thin and might disintegrate during

the application process. If the decals printing is not sufficiently

opaque the underlying colour of the model will show through.

Occasionally, they may be printed out of register where the different colours

are not printed over each other in the right place. However, standards

have been continually increased over the years and the vast majority of decals

are now very good quality.

Decals

printing that are applied well will greatly enhance a model, but when they are

applied badly they will ruin a model that otherwise would have been

excellent. Providing a few basic rules are followed, it is quite easy to

get good results.

Description of Water

Slide Decals

Decals for armoured vehicles are often

restrained. Some AFVs have few markings.

Decals for armoured vehicles are often

restrained. Some AFVs have few markings.

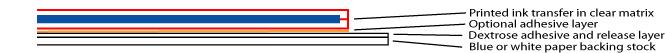

Water

slide decals or transfers consist of several layers. There is always a

sheet of backing paper to which everything else is attached. On top of

the paper is a layer of water soluable glue. The actual markings are

printed on the glue film and on top of that is a carrier film.

When

placed in water for a few seconds the glue will become slippery and allow the

decal to literally slide off the backing paper and on to the model. A

single spot of dishwashing liquid dissolved in the water will help the decals

to slide of the backing paper and on to the model. Hopefully there will

still be sufficient adhesive on the back of the decal to stick to the model.

Surface preparation

It is

vitally important to have a gloss or semi-gloss surface to apply the

decals. If the model is painted with matt/flat paints, then the surface

needs to have a couple of thin coats of gloss varnish, or Klear/Future to give

it some shine.

Matt/flat

paints leave a surface that is microscopically rough. If a decal is

applied to such a surface then it will only make contact with the high points

on the surface of the paint. When dry there will be thousands of

microscopic air pockets under the decal which will appear as 'silvering' and

will look terrible.

Some

modellers will only varnish those parts of the model where decals are to be

placed, but there is a danger of producing a ridge at the edge of the

varnish. Most modellers will varnish the entire model because this is not

only needed for decal application, but also makes it easier to apply filters

and washes to the model.

The

model can always be returned to a matt or semi-gloss finish after decal

application with another coat of appropriate varnish.

Decal Solutions

Although

waterslide decals are intended to stick well to the model, in practice they

only do this in ideal circumstances, such as when there is a perfectly flat

surface. If the surface undulates or has texture, of if the decals need

to fit over or around surface projections, then they need a little help.

Many

companies produce two part decal solutions to help with the application of

waterslide decals. The first part is painted on to the surface of the

model. This makes it easier to slide the decal into the correct position

and improves the adhesion of the decal. The second part is painted on top

of the decal. This softens the decal and helps to make it conform to any

irregularities in the surface. This second solution can be reapplied if

the decal has not fitted well around any surface projections.

Once

the second solution has been applied, the decal may appear to wrinkle and may

look dreadful. However, do not touch it at this stage because it will

be extremely elastic and fragile. As it dries the wrinkles should

disappear and the decal will shrink back on to the surface and cling fast to

any surface details.

These

decal solutions vary in strength between different manufacturers. It is

advisable to experiment a little when you use these solutions for the first

time, or change brands.

When To Apply Decals

This

will vary from model to model and it may be advisable to apply some decals at a

different time to others. Normally, the best time to apply them is just

before weathering, so that they look like they have been weathered with the

rest of the vehicle.

Decals printing are commonly

used on hot rod automobiles and plastic models. They are also used on guitars

as a way of personalizing them.

Decals printing are

great to stick onto backpacks, car windows, skateboards, folders and car

bumpers. Decals can show your views on political matters and your thoughts on

environmental concerns. Decals can allow you to express ideas to the world

without the need for words, displaying pictures and graphics that generate an

emotion or feeling in the observer. You can create your own original decals design

with the use of an easy to operate computer program,

and use the Alps printer that the best decal printer.

Models Printer

applied type:

1.decal printer

2. waterslide decal

printer

3. white color printer

4. gold color printer

5. silver color printer

6. metallic color

printer

Directly print Gold color and Silver color designs includes

photos, decals design,words and texts by alps printers.

The most important is that it can print Gold color ,white color,

metallic color and Silver color on decal stickers.

Gold ink and Silver color ink directly print on stickers.

Process Metallic Color System™

The Process Metallic Color printing enables printers to

consistently and reliably print CMYK process metallic colors and special

effects using their existing equipment and print workflows.

Until now, four-color printing incorporating metallic inks

or metallic substrates was expensive and unpredictable - particularly if more

than one metallic color was required. But the Process Metallic Color System has

changed all this. Now, with only five inks, a single print run can consistently

and predictably produce as many as 250 different metallic colors at a fraction

of the previous cost. The Color-Logic system enables graphic designers to

create a single metallic design that can be executed using offset lithography,

flexography, inkjet and digital processes.

Printing on paper or decal stickers only needs 30 seconds.

Step By Step Guide

The

following shows the application of a decal to Tamiya's 1/35th M113 armoured

personnel carrier. The first stage is to prepare your work area and make

sure you have everything to hand:

Model

Decal sheet

Saucer of water + a drop of dishwashing liquid

Tweezers

Decal solutions

Small brushes (one for each decal solution)

Small scissors

Paper towel

Further Hints

1.

If the decal is thin and the paint underneath shows through

(often the case with white decals) then try painting

over the decals with thinned paint using them as a template.

2.

If the decals have to fit around surface projections, then cut

them into small pieces and apply them separately.

3.

If there are air bubble under a decal when it has dried then

prick it with a pin a few times, paint decal solution on it and press down on

it with a damp paper towel.